In regulated industrial environments, valves must meet strict safety, quality, and performance standards. PTFE Butterfly Valves are widely used across chemical, pharmaceutical, water treatment, and process industries because they not only deliver excellent chemical resistance but also support compliance with international industrial standards. Selecting valves that meet regulatory requirements is essential for safe operations, consistent performance, and long-term reliability.

Importance of Standards in Valve Selection

Industrial standards exist to ensure that valves perform safely under defined operating conditions. Non-compliant valves can result in leakage, equipment failure, or regulatory penalties. PTFE Butterfly Valves designed and tested according to recognized standards provide confidence in pressure integrity, sealing performance, and material compatibility.

Common Design and Manufacturing Standards

PTFE Butterfly Valves are typically manufactured in accordance with globally accepted design norms. These standards define dimensions, pressure ratings, and material specifications, ensuring interchangeability and reliable performance. Compliance with design standards also simplifies installation and integration into existing pipeline systems.

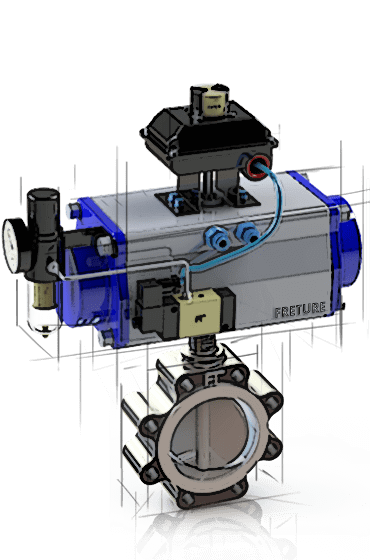

[caption id="" align="alignnone" width="370"]

PTFE Lined Butterfly Valve manufacturer in Mumbai, India[/caption]

PTFE Lined Butterfly Valve manufacturer in Mumbai, India[/caption]Pressure Testing and Leakage Standards

Pressure and leakage testing are critical for verifying valve performance. PTFE Butterfly Valves undergo hydrostatic and pneumatic testing to ensure they can withstand specified pressure limits without deformation or leakage. Leak-tight shutoff performance is particularly important in applications involving hazardous or corrosive fluids.

Material Compliance and Traceability

Material quality is a key requirement in regulated industries. PTFE used in butterfly valves must meet specific chemical and physical properties to ensure long-term stability. Many industries require full material traceability, allowing end users to verify the origin and composition of valve components. This level of transparency supports quality assurance and audit requirements.

Environmental and Emission Regulations

Environmental regulations increasingly focus on controlling emissions and preventing fluid leakage. PTFE Butterfly Valves support low-emission operation due to their excellent sealing characteristics and chemical inertness. Reduced fugitive emissions help facilities comply with environmental safety guidelines and protect surrounding ecosystems.

Hygiene and Clean Process Requirements

In pharmaceutical and food processing industries, valves must meet hygiene and cleanliness standards. PTFE Butterfly Valves feature smooth internal surfaces that prevent contamination and microbial growth. Their non-reactive nature supports compliance with hygiene regulations and ensures product purity throughout the process.

Operational Safety and Reliability

Safety in industrial operations depends on reliable valve performance. PTFE Butterfly Valves are designed to operate smoothly with minimal torque, reducing the risk of mechanical failure. Their resistance to corrosion and wear enhances operational safety, particularly in continuous or high-cycle applications.

Documentation and Quality Assurance

Standard-compliant PTFE Butterfly Valves are supplied with inspection and test documentation, including pressure test reports and material certificates. Proper documentation supports regulatory compliance, simplifies audits, and ensures confidence in valve performance throughout its service life.

Industries Benefiting from Standard-Compliant PTFE Butterfly Valves

Chemical and petrochemical processing

Pharmaceutical and biotechnology manufacturing

Water and wastewater treatment

Food and beverage processing

Specialty industrial applications

PTFE Butterfly Valves designed to meet international standards play a vital role in ensuring industrial safety, regulatory compliance, and consistent performance. Their ability to combine chemical resistance with certified quality makes them a reliable choice for critical applications. By selecting standard-compliant PTFE Butterfly Valves, industries can achieve safer operations, reduced risk, and long-term process reliability.